A Quality First philosophy means that manufactured products and services receive advanced quality assurance. Products are evaluated for continual improvement and normally exceed customer specifications.

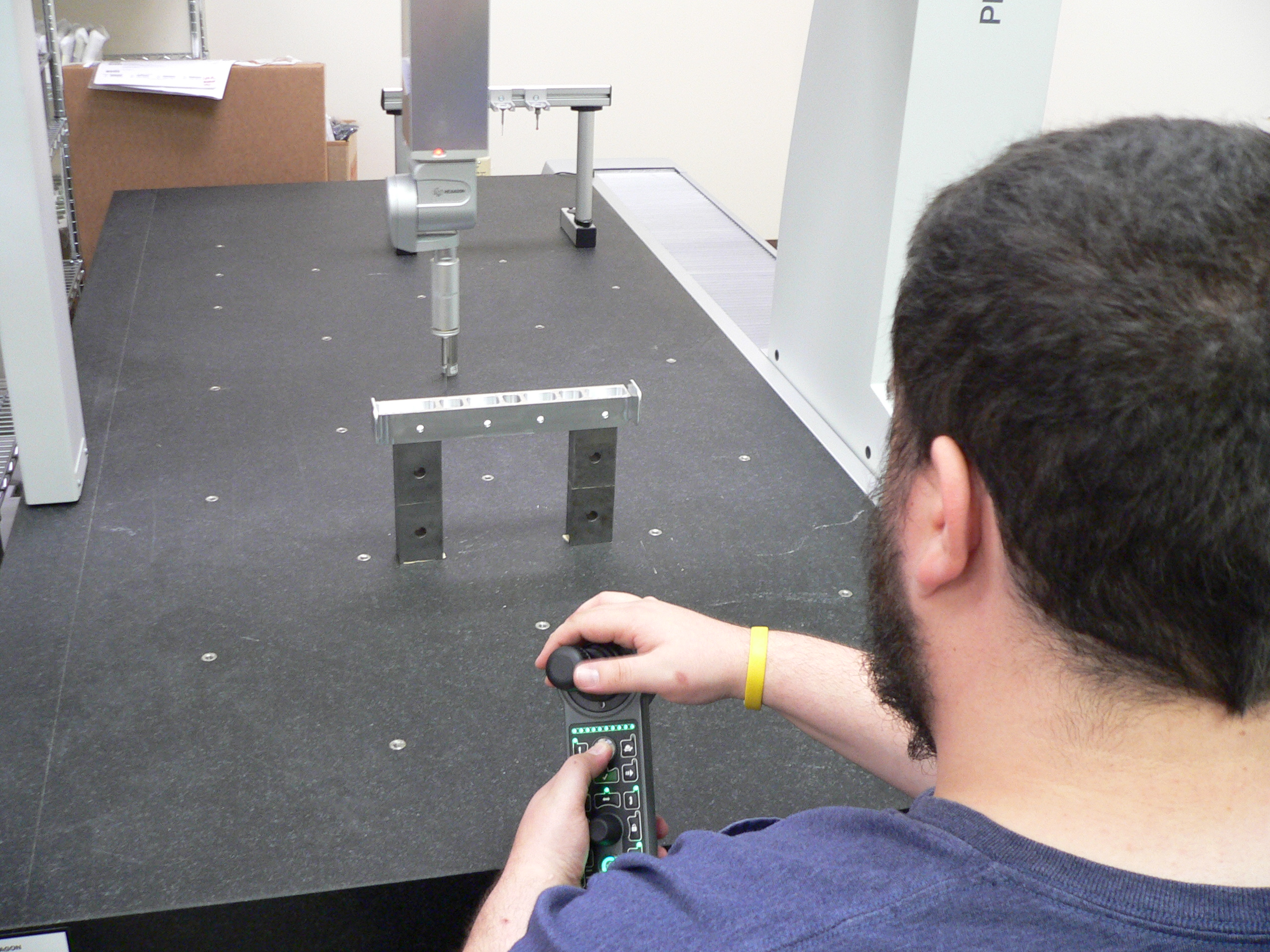

KMI’s Quality Assurance Department is equipped with modern state of the art inspection instruments. It is third party certified and governed by written procedures as mandated and set forth in AS 9100 REV. D And ISO 9001:2015 Quality management Systems-Aerospace-Requirements.

KMI’s calibration system is in compliance with ANSI / NCSL Z540-1 and ISO 10012-1. KMI’s Quality Assurance Department is in a climate controlled area to ensure that tolerances and quality are maintained.